CAMX 2025: Pushing Composites Innovation Forward

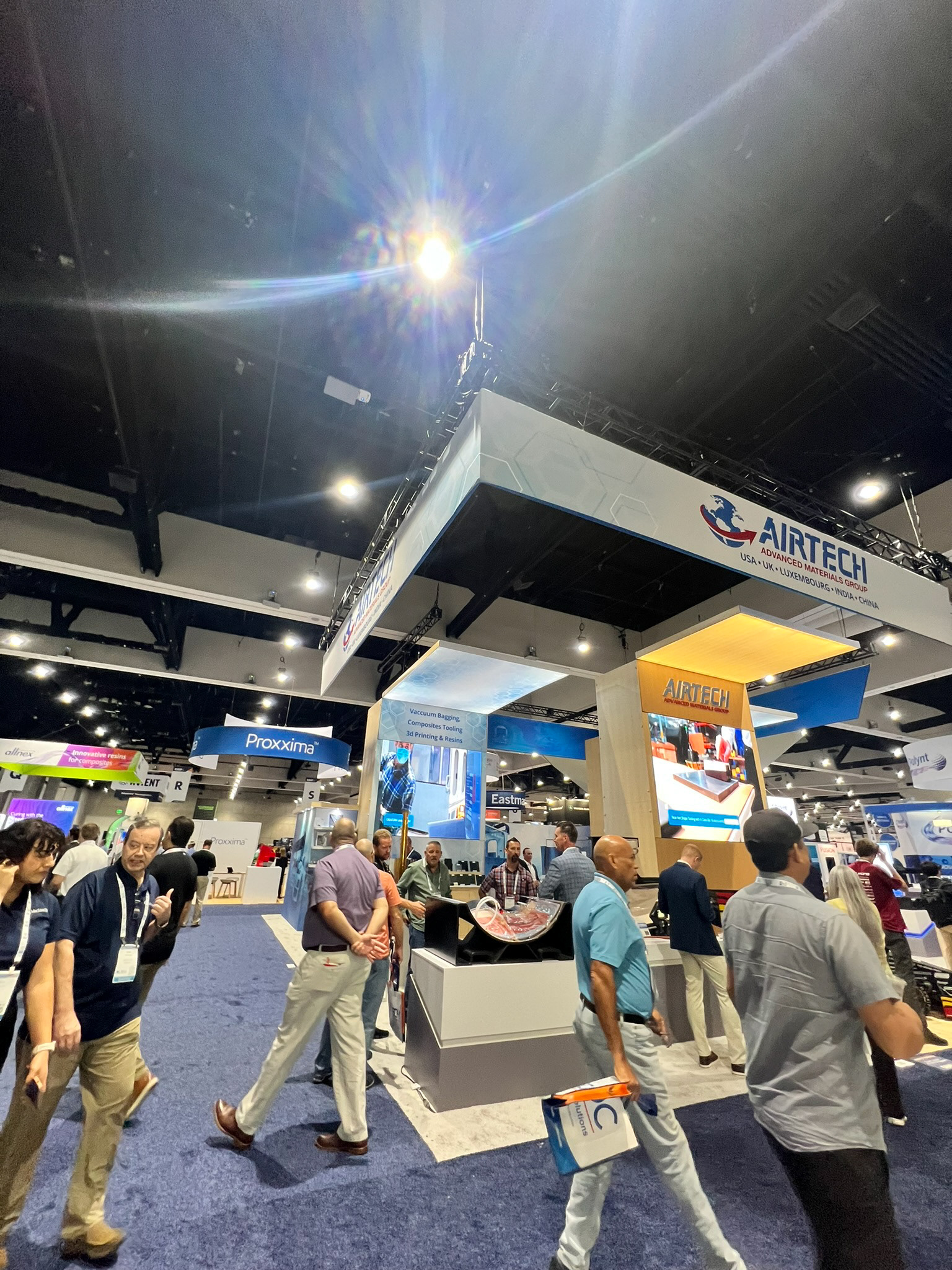

CAMX 2025 (September 8-11, Orlando, FL) was an exciting showcase of what’s next for composites and advanced materials. I was drawn to the cutting-edge advances in automation machinery, streamlining production like never before. Photogrammetry and shearography applications stood out for their precision in quality control, while the year-over-year growth of large-scale AMF tools showed the industry’s bold direction. The introduction of Ceramic Matrix Composites (CMC) for high-performance uses, like turbine engines, was a real game-changer. More insights to come!

Large-scale additive manufacturing (AM) tools were a significant topic at CAMX 2025, with many more exhibitors showcasing these technologies compared to previous years. The increased focus highlights the industry's push toward automation and faster production.

One company at the forefront is Airtech Advanced Materials Group, which has a division dedicated to AM, offering a full-service solution for tooling, including their Dahltram® resins. These specialized resins, which are reinforced with carbon fiber, are designed to have a low coefficient of thermal expansion (CTE), making them more suitable for high-temperature applications like autoclave molds. This directly addresses one of the primary criticisms of AM tools: their potential for issues with CTE, which can affect their performance in compression molding and other high-heat processes.

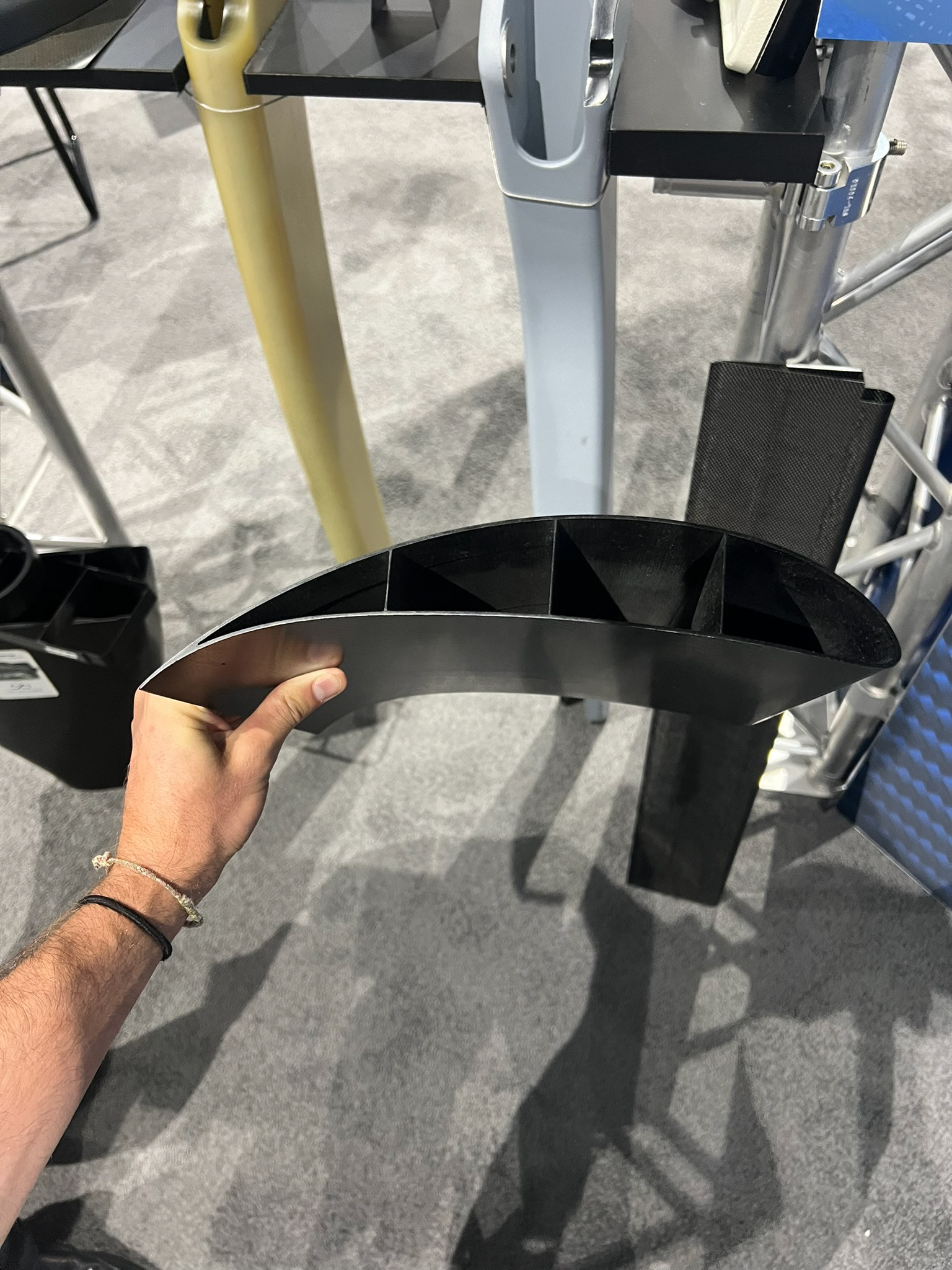

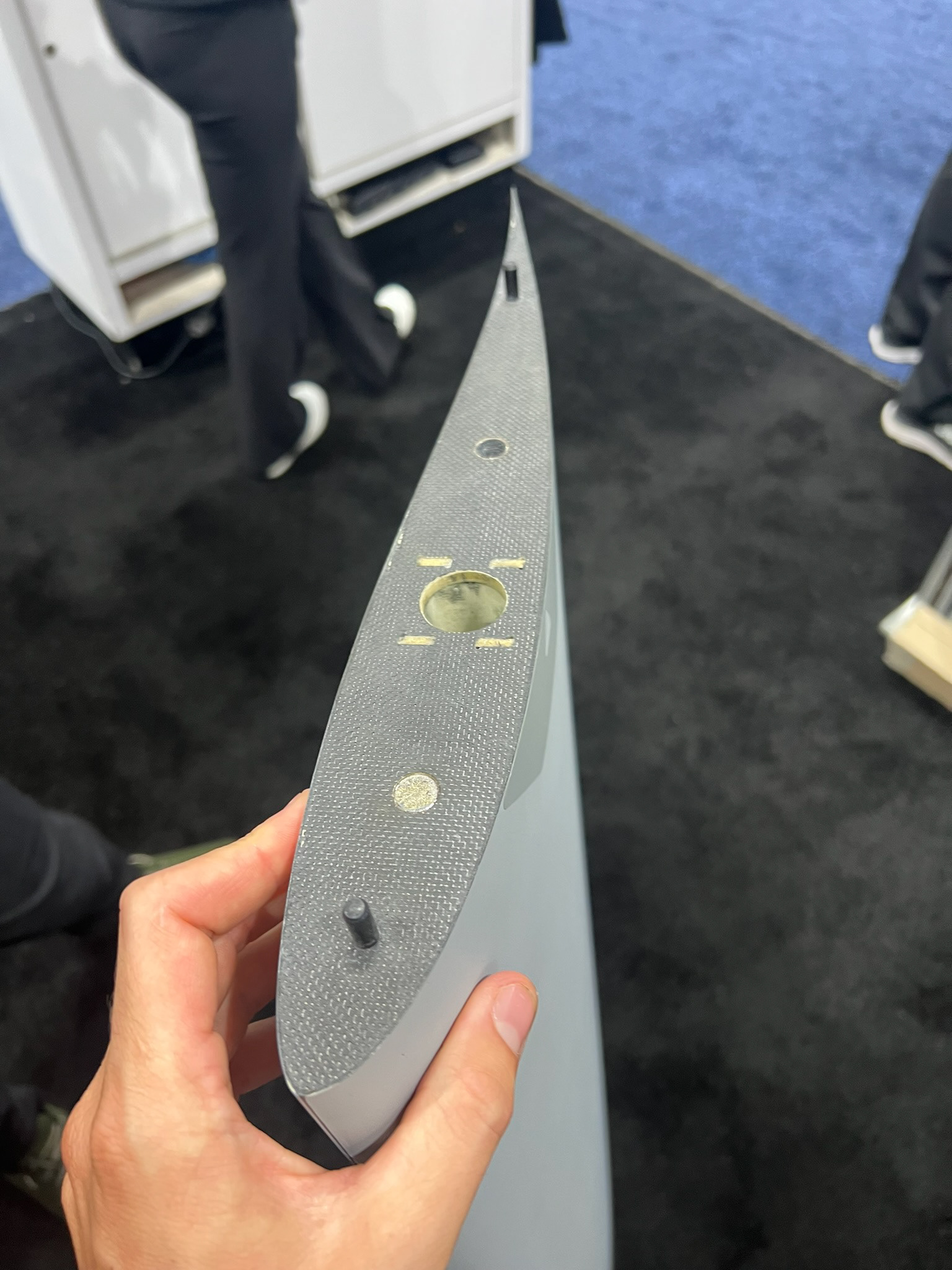

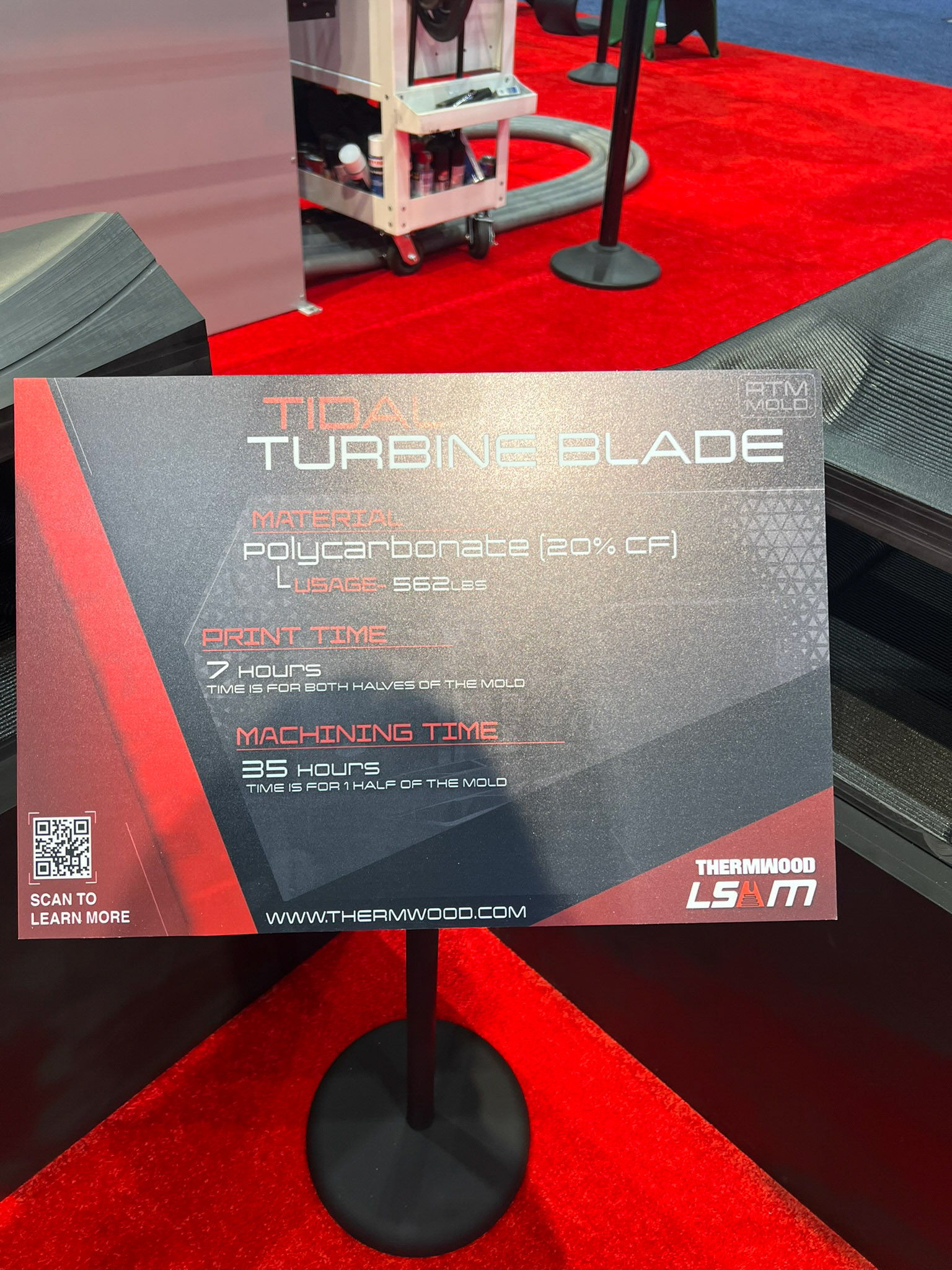

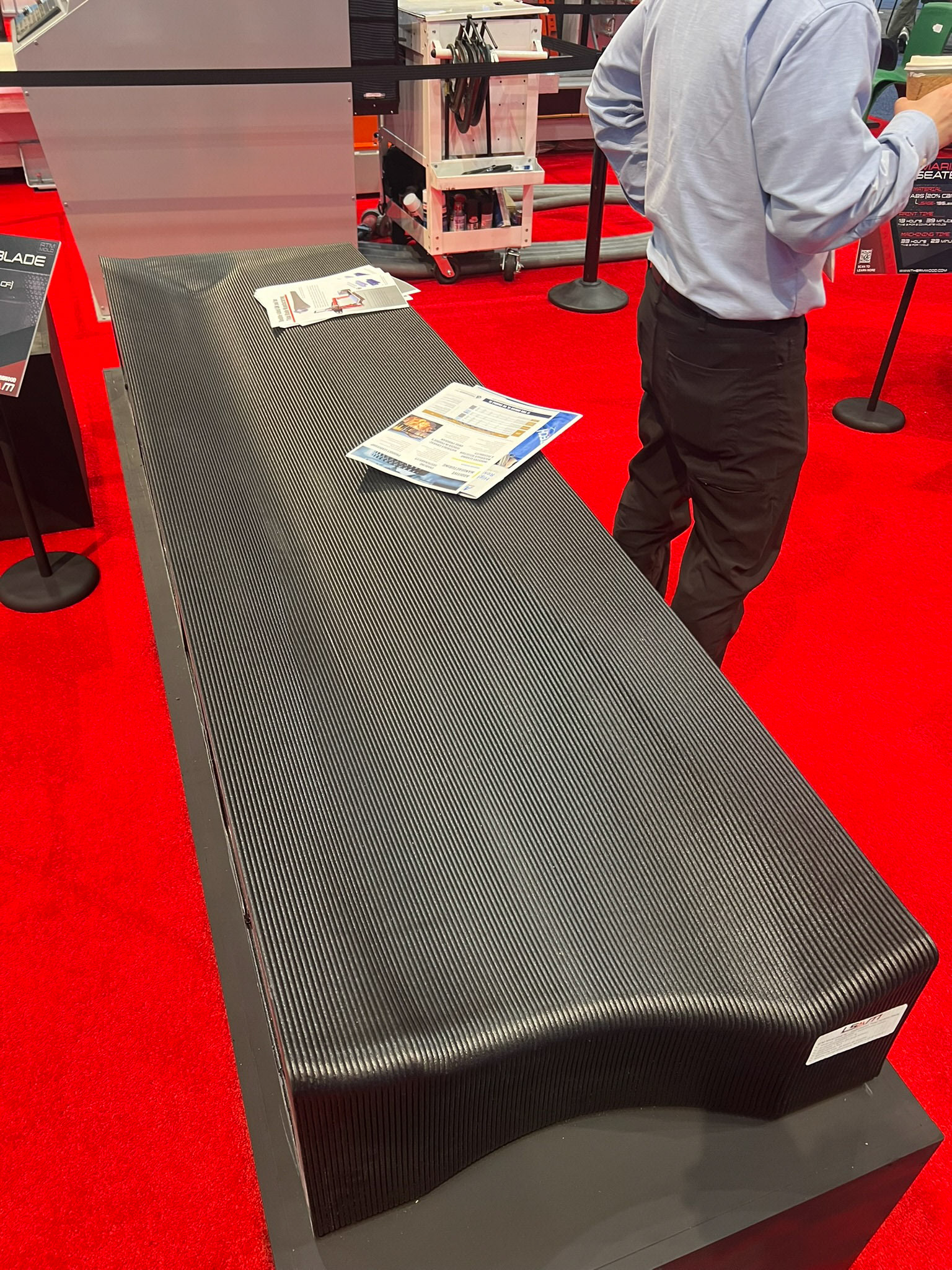

Thermwood is a major player and is considered a leader in the large-scale AM tooling space. Their LSAM (Large-Scale Additive Manufacturing) systems are known for their ability to both 3D print and then CNC machine a part on the same platform. This "near-net-shape" process is designed to create large, durable tools and molds from high-temperature thermoplastic composites.

Some other interesting papers...